Robotics in building cleaning services

People cannot be replaced in building cleaning services, as much of the work can only be done manually. However, due to the growing shortage of skilled labour in many countries, it is becoming increasingly important to reduce time-consuming activities and work efficiently. The use of robotics in building cleaning services is nothing new, but some models now work so autonomously that they represent a clear reduction in the workload for certain applications. Easy operation and high safety standards for working among the general public also mean they can be implemented for a wide range of application scenarios, from supermarkets and hospitals to airports.

Autonomous and safe cleaning robotics: what's it all about?

It's still uncommon to spot an unmanned scrubber dryer robot or carpet brush vacuum robot going about a cleaning task by itself. Although cleaning robots have been around for a while now, they're still not particularly widespread. But with the new degree of autonomy and safety that has been achieved, this is set to change.

When the machine works independently

You might think "autonomous" always refers to something that works truly independently – but a look at the automotive industry shows that this is not correct. Autonomous driving is actually more precisely defined by five different levels: assisted, semi-automated, highly automated, fully automated and autonomous driving. Each of these denotes a different level of human involvement, which plays less of a role with every stage.

Although cleaning robots are not quite as complex, they are similarly intended to reduce the need for human intervention as much possible. Machines are now available that can control a docking station themselves. There, they are automatically recharged and filled with the necessary supplies, with no need for any operator intervention.

Scrubber dryer robots can now also clean right up to the edges of a floorspace, eliminating the need for any follow-up work. Machines with the appropriate software and sensor technology, as well as the ability to reverse independently, can even perform manoeuvres to free themselves from dead ends. Reports are also compiled for each deployment, making it clear where cleaning has already been carried out and where it has not.

Safety is paramount

Robots are only permitted to be deployed in public areas if they fulfil clear safety requirements. Laser scanners, 3D sensors and ultrasonic sensors now facilitate 360° environment detection, meaning people and other moving obstacles as well as stationary objects can be reliably detected. Depending on the model, the safety features are certified in accordance with the safety standards of CSA (North America) and/or IEC (Europe). In any event, an external authority must always confirm that the robot can be operated safely in compliance with the relevant standards.

Misgivings about robots? There's no reason to worry

Although robots have become commonplace in many fields – for example, in medical technology or in production plants – people still have certain misgivings when it comes to deploying them in direct points of contact in everyday life. However, it's now actually very simple to handle and integrate these.

Simple handling, easy route planning

When scrubber dryer robots first came onto the market, only service technicians with the necessary technical equipment and programming expertise were able to create routes for them. Reflective landmarks had to be hung up everywhere for navigation. Since then, however, cleaning robots have become much easier to use, thanks to better sensors, higher quality of data and more advanced operating concepts.

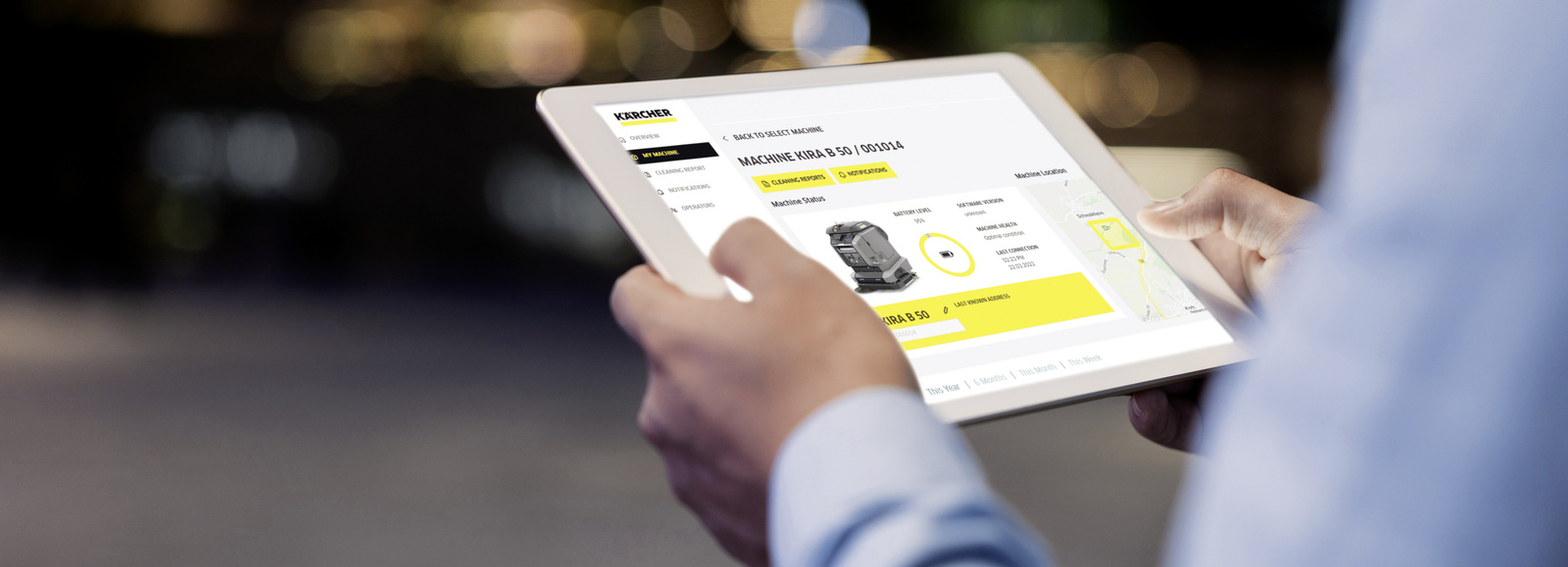

Routes can be created, corrected and combined independently by the user. Depending on the model, illustrations and step-by-step instructions also provide assistance with this. When programming a route, the user selects a starting point, which is usually marked with a code. The robot then reads this code and follows the intended path. Alternatively, some robots can independently process surfaces to be cleaned, even if these were previously bypassed. Users can also call up the status of the machine at any time.

Tip 1:

When the robot learns routes in retail spaces, for example, it is recommended that these are kept clear of point-of-sale (PoS) displays during the teach-in phase. This means that if the displays are ever removed, the robot will be able to clean the freed-up areas without needing to be taught in again.

Tip 2:

In practice, it has proven to be most effective to limit routes to a length of 30 to 60 minutes. Individual routes can then be linked together if necessary.

Where does it make most sense to deploy robotics? Building cleaning services in transition

In theory, robots might be perceived at first glance to present competition to traditional building service contractors, since building operators are able to acquire their own fleets. However, it is clear that a coherent cleaning concept can only be implemented with the expertise of specialist staff. The attainable degree of automation in building cleaning services also has clear limits, since many activities need to be performed manually.

Monotony versus complexity

Wherever monotonous cleaning tasks in fields such as logistics, retail, production, airports or healthcare require a lot of effort and accordingly generate high costs, it makes sense to deploy robotic solutions instead. If this workload is reduced, cleaning staff are free to tackle other, more complex tasks for which they previously had little or no time. This is a great advantage, since the increased need for cleanliness and hygiene in public spaces has actually made building cleaning services more complex, rather than simpler.

The example of scrubber dryer robots

Scrubber dryer robots can significantly reduce the effort required for floor cleaning. Depending on the model, they are suitable for use in medium to large areas and can manoeuvre safely in confined spaces. When these cleaning robots are able to replenish their resources independently, they can clean several thousand square metres per day without any human intervention. In order to attain very good results on a consistent basis, the water volume, detergent dosing and work speed can be preset according to the degree of soiling.

The example of carpet brush vacuum robots

Large carpeted areas are costly and time-consuming to clean. Carpet brush vacuum robots with powerful batteries can relieve cleaners of this arduous task. Robots that can cover a large area with high cleaning performance make a particularly valuable contribution to increasing productivity and cleaning quality.

Pre-deployment planning is fundamental

Although the machines operate autonomously, the expertise of humans is still required to ensure that robot deployments are properly planned. It is important to consider where in the building high levels of soiling are to be expected – for example, in the entrance area – as well as which areas are less frequented and will therefore require less regular cleaning. In order to cut down the robot's travel time and plan efficient routes, it is important to determine in advance where the position codes for the start of the route and the docking stations for charging and replenishment should ideally be located.

Suitable products for your area of application

Find a wide range of technology at lightning speed – with the Kärcher Professional product finder

In no time at all, we'll show you the exact Kärcher Professional machine that best suits your specific cleaning task.