Reference BMW Group Munich

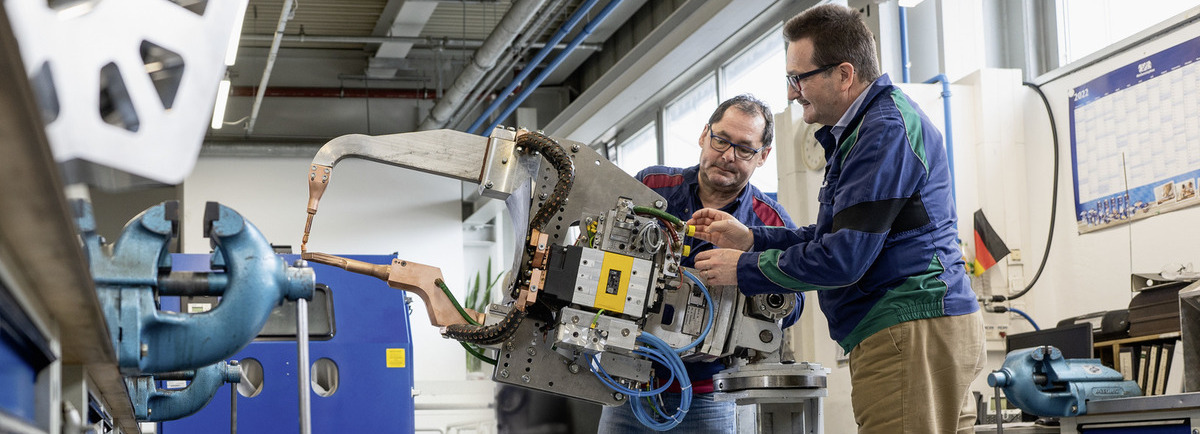

A conversation with Alfred Weber (Foreman, Central Workshop, BMW Group plant, Munich) about the need to eliminate waste and always be ready.

Preventing waste

In the central workshop of the BMW Group plant in Munich, the L2P dry ice blaster has improved logistics and processes, much to the satisfaction of workshop foreman Alfred Weber.

Challenge

Dry ice was previously being bought in in order to clean tools by means of dry ice blasting. Due to the fluctuating workload, either dry ice was left over or there was none available when it was needed.

Solution

The L2P dry ice blaster produces dry ice on demand, meaning that work can be carried out at any time and waste can be prevented.

You are a foreman at the central workshop of the BMW plant in Munich. What falls under your area of responsibility and what are the greatest challenges you face in your work?

We clean spot welding guns and grippers as well as adhesive equipment on robots. We also carry out machining with turning and milling machines, as well as 3D printing. Before we can repair a tool, it needs to be cleaned. We can use mechanical aids for light soiling, but in many cases we use dry ice blasting. The greatest challenge for us is that we never know which tools are coming in for

repair when or what condition they will be in. This means that 90% of our work cannot be planned – around 700 articles from each tool category are currently in circulation.

What is important to you when working with your suppliers?

How a business partner communicates with me is important. Are my needs being met, are there any suggestions for improvements, is there an honest answer to critical questions? We all know that there is no single solution to every problem and that every solution has its pros and cons. I want to be able to speak openly about this with my suppliers. Keeping appointments is also important to me – you can always cancel a meeting or call to say you’re stuck in traffic. But to leave someone waiting without letting them know is unacceptable.

Together with Kärcher, you have optimised the cleaning of spot welding guns. What was the problem with your previous way of working and how has the new solution changed things for the better?

As we need to use dry ice to clean spot welding guns and other tools, we invested in a blasting cubicle and a dry ice blaster some time ago. To make sure we were always ready, however, dry ice had to be delivered every week. Sometimes we had no tools to clean, which meant that the dry ice evaporated. Or we had so many tools to clean that we didn’t have enough. This was unsatisfactory in terms of cost and logistics, but this is always the case with dry ice blasting. The dry ice blaster from Kärcher has eliminated this problem, as it produces dry ice at the precise moment it is needed. This means we are always ready to work.

Do you use other Kärcher products and if so, why?

Yes, we do actually. During a subsequent meeting, we touched on the subject of industrial vacuums. Our milling machines are cleaned once a week, which involves vacuuming up chips. The technician showed me the vacuum cleaner, which I knew by the name of Ringler – and it was exactly what we needed.

Which aspects of Kärcher as a company impress you the most?

I have been familiar with Kärcher since childhood thanks to its famous high-pressure cleaners. It is an established company with a very good reputation. I was truly surprised to discover that Kärcher also manufactures dry ice blasters and covers a far broader range of industries than I realised.

If you could ask for anything, which innovation( s) would you like to see next from Kärcher?

Honestly, an L2P dry ice blaster with more power (L2P = Liquid to Pellet). With more power, we would be able to use it for all cleaning tasks, including the cleaning of adhesive equipment, for example. If you ask me, that would be the key to selling L2P to industrial customers on a grand scale.

What`s changed? Facts and fugures

Sometimes it’s obvious that an existing process is inefficient, but there is no other solution. All the better when the right product appears out of nowhere.

Challenge

In order to guarantee smooth production, spot welding guns and other tools need to be cleaned and maintained.

- The frequency and timing of work cannot be planned.

- For dry ice blasting, the dry ice must be purchased in advance, which means that large quantities often evaporate having not been used.

Solution

The fact that there was an existing infrastructure for dry ice blasting meant that the new L2P dry ice blaster could be purchased and used straight away.

The dry ice is produced by the machine from CO₂, which can be stored in bottled.

- This makes cleaning possible at any time, prevents waste and completely eliminates the need for logistical planning for the purchase of dry ice.

Value preservation for long-term use of the tools. Downtimes in production are minimised thanks to prompt cleaning and maintenance of the tools.

Increased productivity in the maintenance department, as cleaning can be carried out at any time.

The investment in an L2P machine pays for itself extremely quickly, as no dry ice is wasted.

Considerable cost savings every year, as only as much CO₂ as is needed has to be bought.